ITEM SPECIFICS

-

Brand

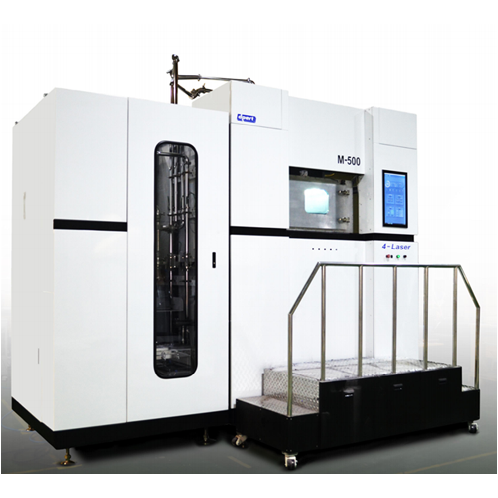

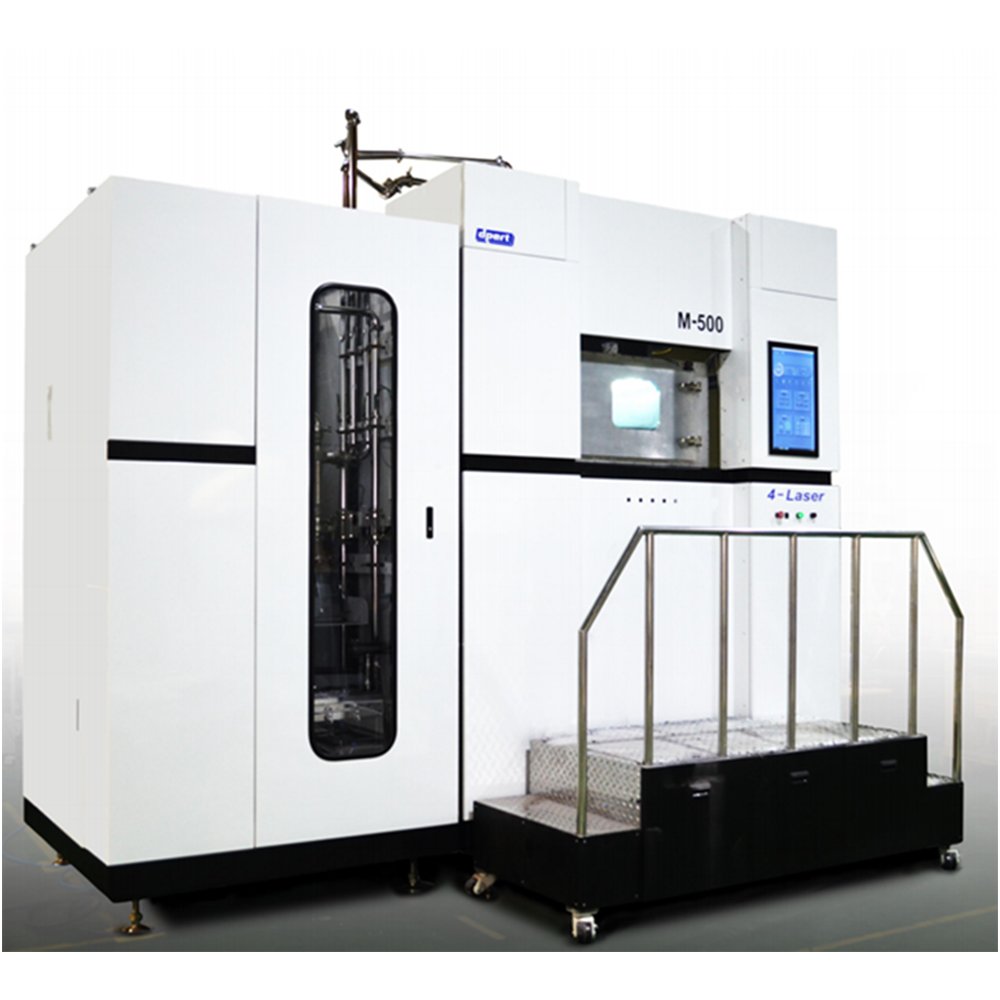

Model M500DPERT

-

origin

Republic of Korea

-

Size(Capacity)

1,750(W) × 2,400(D) × 3,300(H) mm (Build volume: 500 × 500 × 500 mm)

-

Material

Heavy-duty steel frame, stainless build chamber, aluminum panels; industrial PC; 4-laser scan system

-

Weight

3,400kg

-

Function

3D printer

-

Style

4-laser architecture for speed and productivity; 0.03–0.10 mm layers

PRODUCT DESCRIPTION

The DPERT M500 is a four-laser PBF platform with a 500 × 500 × 500 mm build volume engineered for fast, repeatable production of medium-to-large parts.

Layer thickness from 0.03 to 0.10 mm and multi-laser scanning deliver excellent surface quality and throughput.

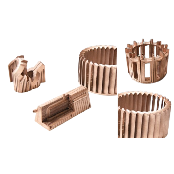

The system processes a wide range of materials including pure titanium, titanium alloys, Inconel 718/625, Hastelloy, stainless steels, aluminum alloys, nickel alloys and maraging steels.

With argon atmosphere control and robust thermal management, the M500 is suited for aerospace/defense structures, energy and semiconductor components, and automotive molds and tooling.

Optional automatic powder handling enhances safety and productivity. Configuration, utilities and bed-heating availability are finalized at order stage.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Document against Payment : D/P

- Telegraphic Transfer : T/T

- Name : Dae Woong

SHIPPING

Shipping from :

Republic of Korea

- Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

DAEGUNTECH CO., LTD.

The person in charge

KI SOO SHINAddress

Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

Homepage

DAEGUNTECH CO., LTD.

Introduction

DAEGUNTECH CO., LTD. Has been preparing for the future sith stable performance and quality. We are the company which jumps up to be a leading company in the world for the future with outstanding technique and several manufacture experience, and everyone, with one mind, is trying to be the best to each field.

We give thanks to all customers’ support and our outstanding technology, and a variety of manufacturing experience of all employees working hard to become the best in their fields in union.

DAEGUNTECH will further invest on our technology and research and development for better and precise manufacturing to achieve and challenge for new possibilities of exporting our products around the world.

Customer's trust, management transparency, revolution and industrial equipment hardware will take us forward

-

- Business Type :

- Manufacturer

-

- Main Product :

- Metal Additive Manufacturing Cable Harness Assemblies

-

- Established :

- 2004-08-26

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 101~500 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 5,716,206

-

- Number of foreign trade employees

- 101~500 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- DAEGUNTECH CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★