ITEM SPECIFICS

-

Brand

Model DG-AM-PARTS (per drawing)DPERT

-

origin

Republic of Korea

-

Size(Capacity)

Per drawing / STEP, STP, STL, 3MF (build rules provided at quotation).

-

Material

Titanium (Ti-6Al-4V), Inconel 718/625, Hastelloy, Stainless steel, Aluminum alloys, Pure copper

-

Function

Build to customer 3D data via Laser Powder Bed Fusion; finish to spec

-

Features

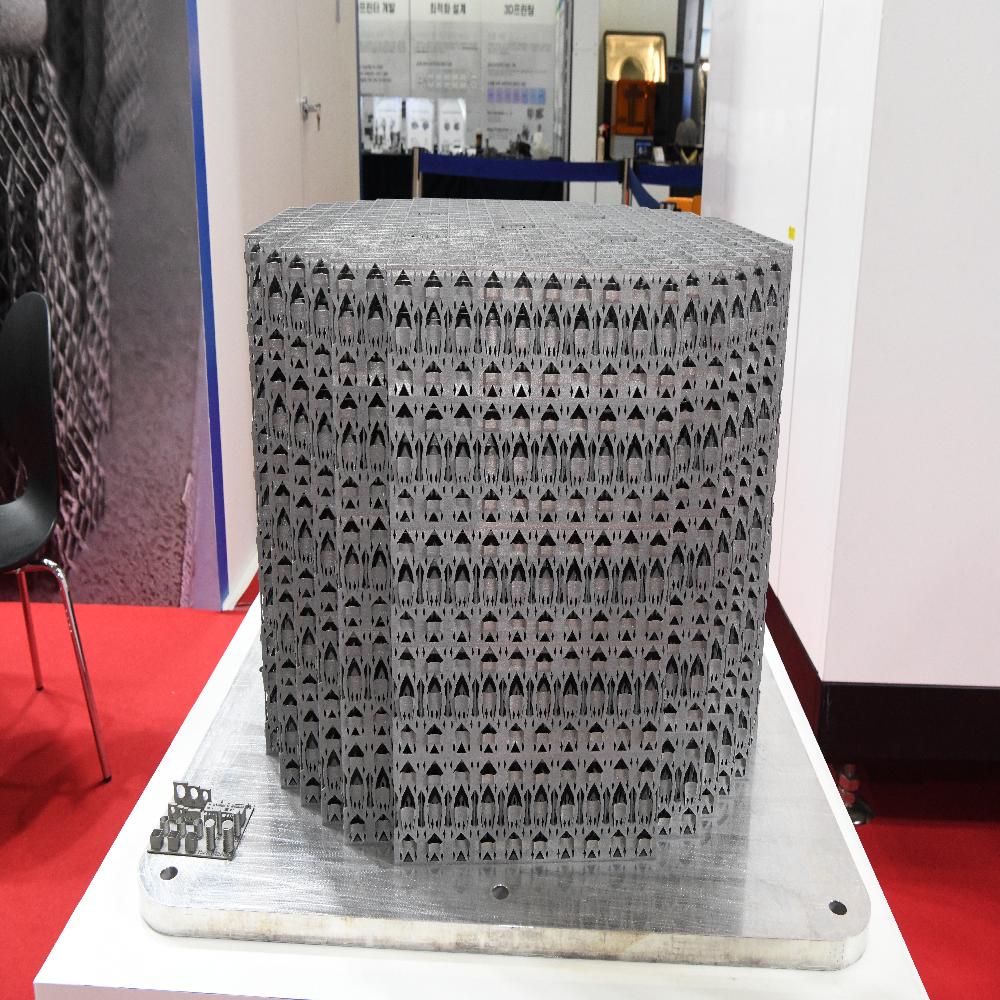

Max single-part envelope up to 800×800×800 mm (M800)

PRODUCT DESCRIPTION

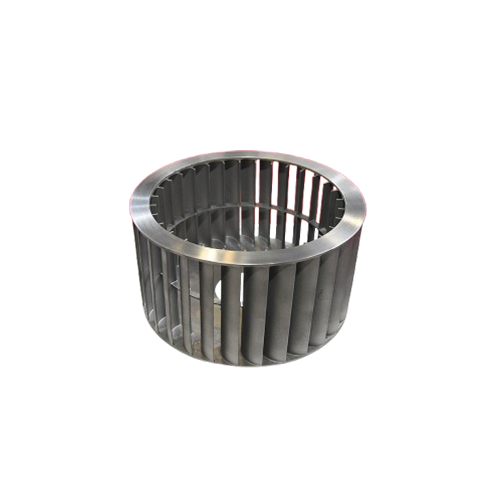

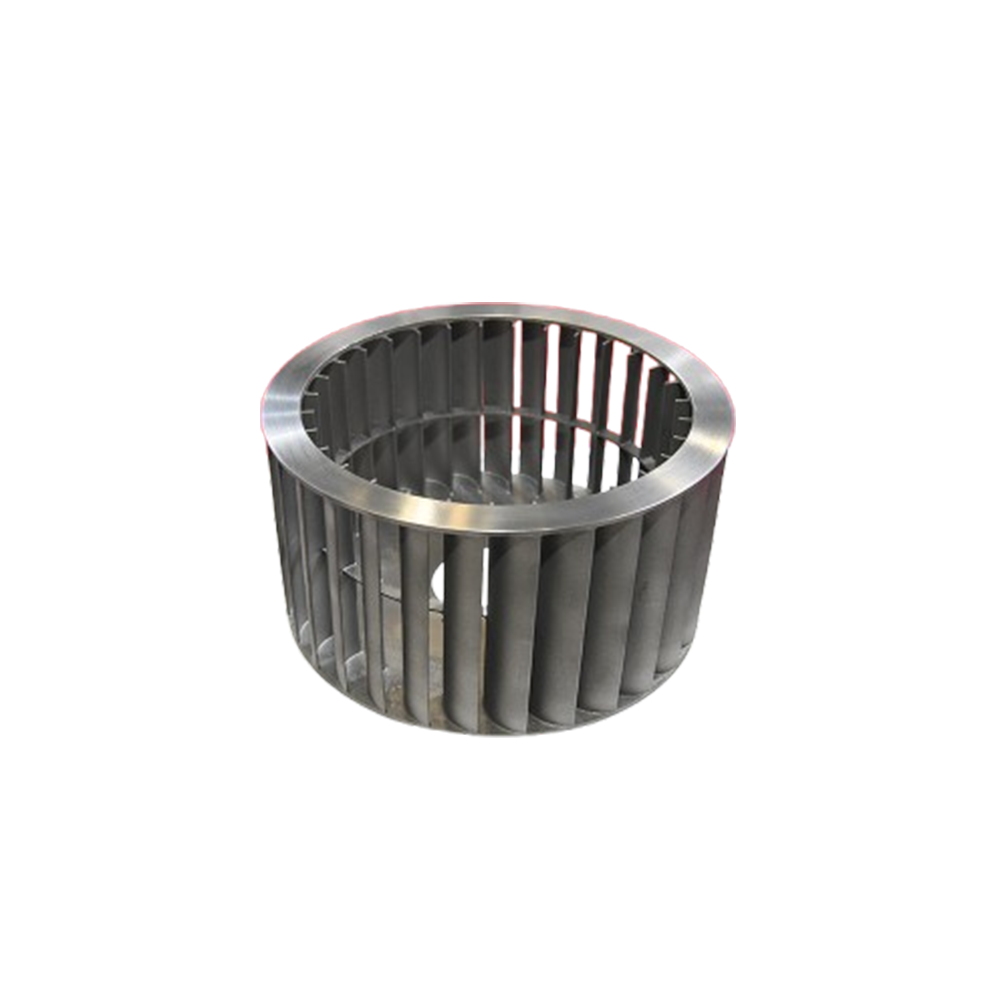

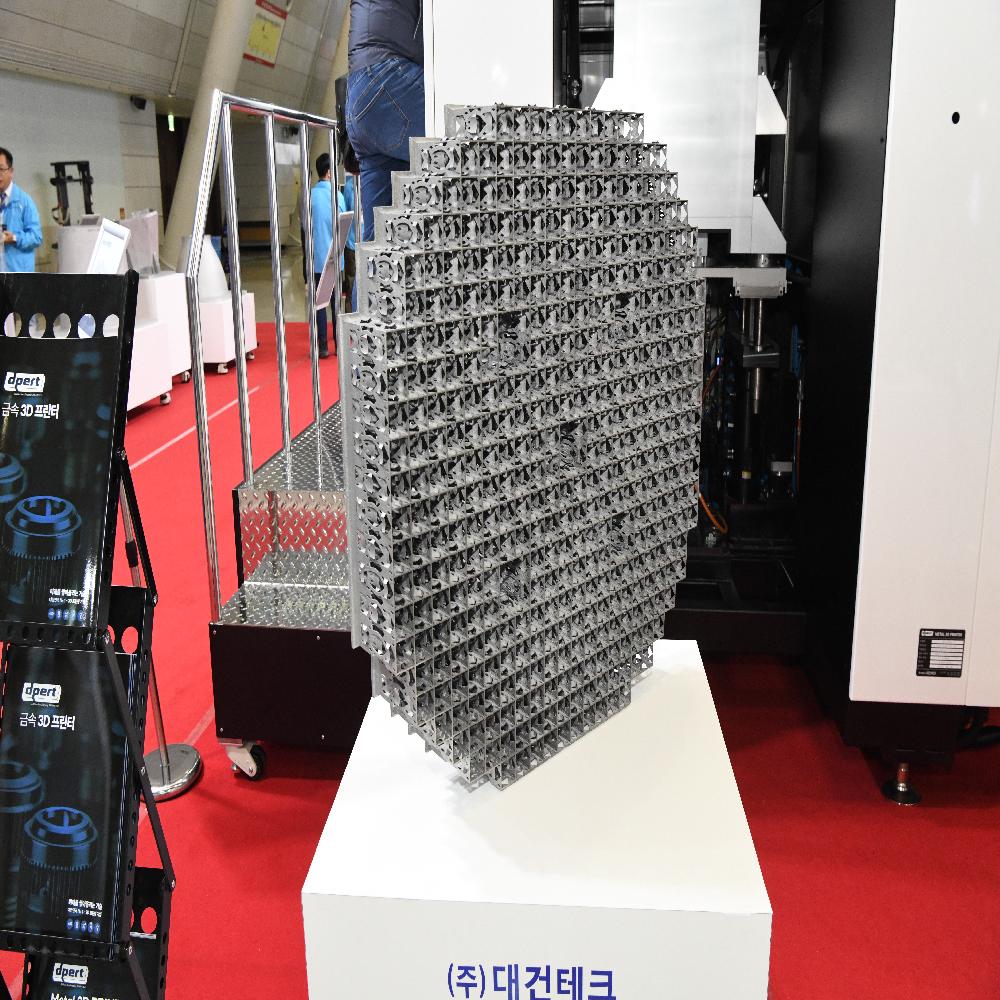

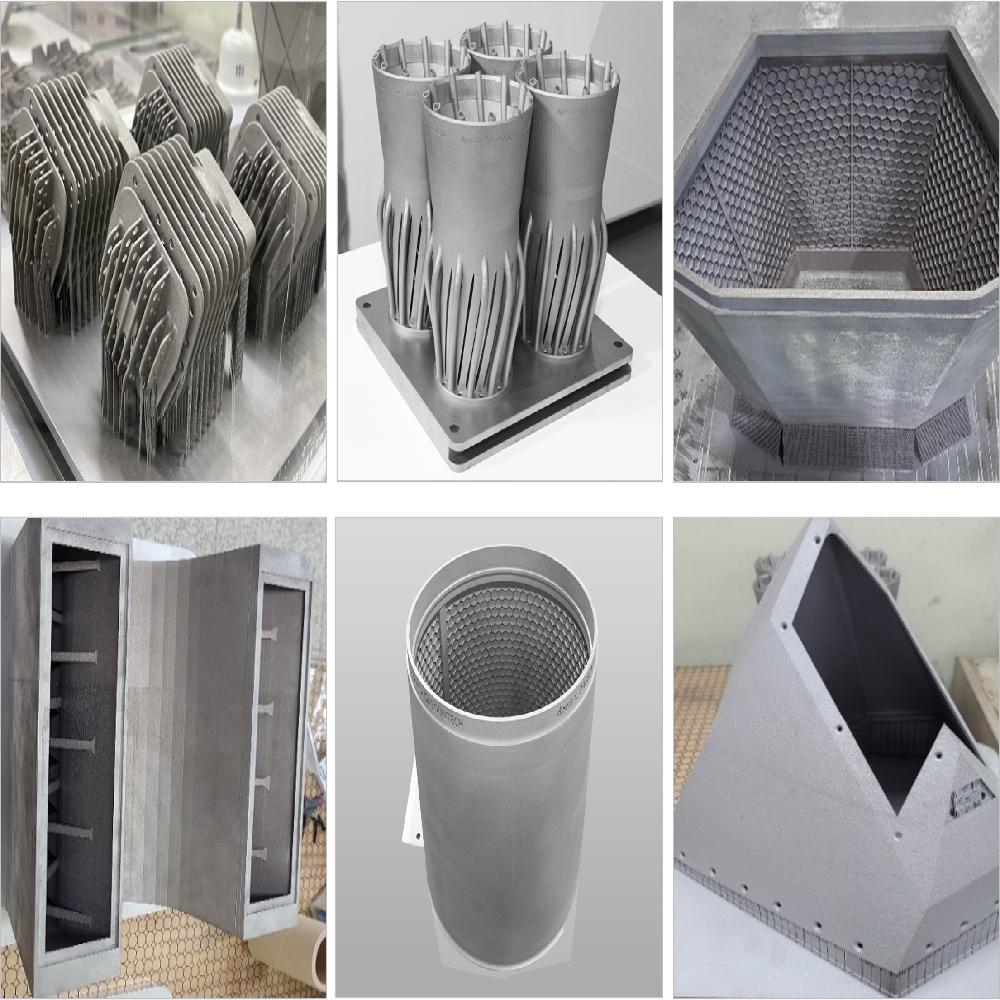

Daegun Tech manufactures build-to-print metal components using Laser Powder Bed Fusion across a full range of alloys—titanium, nickel superalloys, stainless steel, aluminum and pure copper.

Our process starts with a DFM/DFAM review where we check minimum walls, overhangs, lattice rules and powder removal paths, then prepare data in Magics with the Materialise Build Processor to keep slicing, support design and exposure parameters consistent. Parts are printed on calibrated systems with x-layer thickness from 0.03 to 0.12 mm, followed by stress relief, support removal and, where appropriate, HIP, precision machining and surface finishing such as bead blast, anodize or passivation.

Typical dimensional accuracy is ±0.05–0.20 mm depending on geometry and alloy; density targets and roughness values are agreed at quotation. We provide full lot traceability to powder batch, maintain traveler records, and can supply FAIR/Delta FAIR, CoC, chemical/mechanical test results and NDT (X-ray/CT or dye-penetrant) on request. Applications span aerospace and defense brackets, RF waveguides and shields, semiconductor thermal hardware, medical instruments and conformal-cooled mold inserts.

For prototyping, lead times are often 2–4 weeks; low-rate production is typically 4–8 weeks depending on post-processing and inspection scope. Finished parts are protected with VCI film, foam and export-grade wooden crates.

By combining design freedom with controlled quality gates, our PBF service helps you consolidate assemblies, reduce weight and move from concept to reliable, repeatable parts with fewer suppliers and shorter schedules.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Document against Payment : D/P

- Telegraphic Transfer : T/T

- Name : Dae Woong

SHIPPING

Shipping from :

Republic of Korea

- Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

DAEGUNTECH CO., LTD.

The person in charge

KI SOO SHINAddress

Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

Homepage

DAEGUNTECH CO., LTD.

Introduction

DAEGUNTECH CO., LTD. Has been preparing for the future sith stable performance and quality. We are the company which jumps up to be a leading company in the world for the future with outstanding technique and several manufacture experience, and everyone, with one mind, is trying to be the best to each field.

We give thanks to all customers’ support and our outstanding technology, and a variety of manufacturing experience of all employees working hard to become the best in their fields in union.

DAEGUNTECH will further invest on our technology and research and development for better and precise manufacturing to achieve and challenge for new possibilities of exporting our products around the world.

Customer's trust, management transparency, revolution and industrial equipment hardware will take us forward

-

- Business Type :

- Manufacturer

-

- Main Product :

- Metal Additive Manufacturing Cable Harness Assemblies

-

- Established :

- 2004-08-26

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 101~500 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 5,716,206

-

- Number of foreign trade employees

- 101~500 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- DAEGUNTECH CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★